10.1 SYSTEMS ENGINEERING

In the foregoing chapters the design of the major liquid rocket engine subsystems and their components has been discussed. By themselves, these subsystems cannot fulfill a useful purpose. Only when integrated into a whole will they function as a system and produce for what they were designed: thrust. While the engine designer thus must view the complete rocket engine as the system, he should not lose sight of the fact that, to the stage builder, the engine is again a subsystem. (In fact, to the launch vehicle systems engineer, the stage in turn becomes a subsystem, in addition to other stages, ground-support equipment, launch facilities, downrange stations, etc.)

In an earlier chapter the major engine parameters requiring optimization during implementation of rocket engine design were defined. It is apparent that the subsystems discussed will not form an optimized complete system unless they are designed for one another with this goal in mind from the beginning. The subsystems presented in the foregoing chapters have become highly specialized fields during recent years. Their designers and developers often have only a rather general feeling for the functions and peculiarities of the other subsystems. Their concentrated effort will not come about unless it is guided by an important function: systems engineering.

In most rocket engine projects this function is assigned to the "systems engineer," commonly called project engineer or project manager. In conformance with user requirements, he has the job of establishing all ground rules and performance parameters (ch. II) and to subsequently optimize them through complete integration of all subsystems during the entire design and development period.

Because of the previously discussed interaction of funding, time, and reliability, the project engineer must be a good manager, too, in addition to his engineering qualification. From his superiors he needs adequate authority, commensurate with his responsibilities. He must have a broad and thorough understanding of the various disciplines governing the design and development of the subsystems. In view of the latter's high specialization, he cannot be expected to have a complete education in all these disciplines. However, in the words of Du Pont's Crawford H. Greenewalt, he must have "the ability to create a harmonious whole out of what the academic world calls dissimilar disciplines," and that in this respect his job may be compared to that of a "symphony conductor under whose hand a hundred or so highly specialized and very different talents become a single effort of great effectiveness."

The job of systems integration does not merely assure that all parts physically fit together, although this certainly is a first basic requirement. Wherever parts and subsystems join, an interface exists, a demarcation line between these systems. This may be a bolt hole pattern; a flow of fluid, heat, or electrical current; an exchange of forces, loads, or torques; or a complex dynamic interaction.

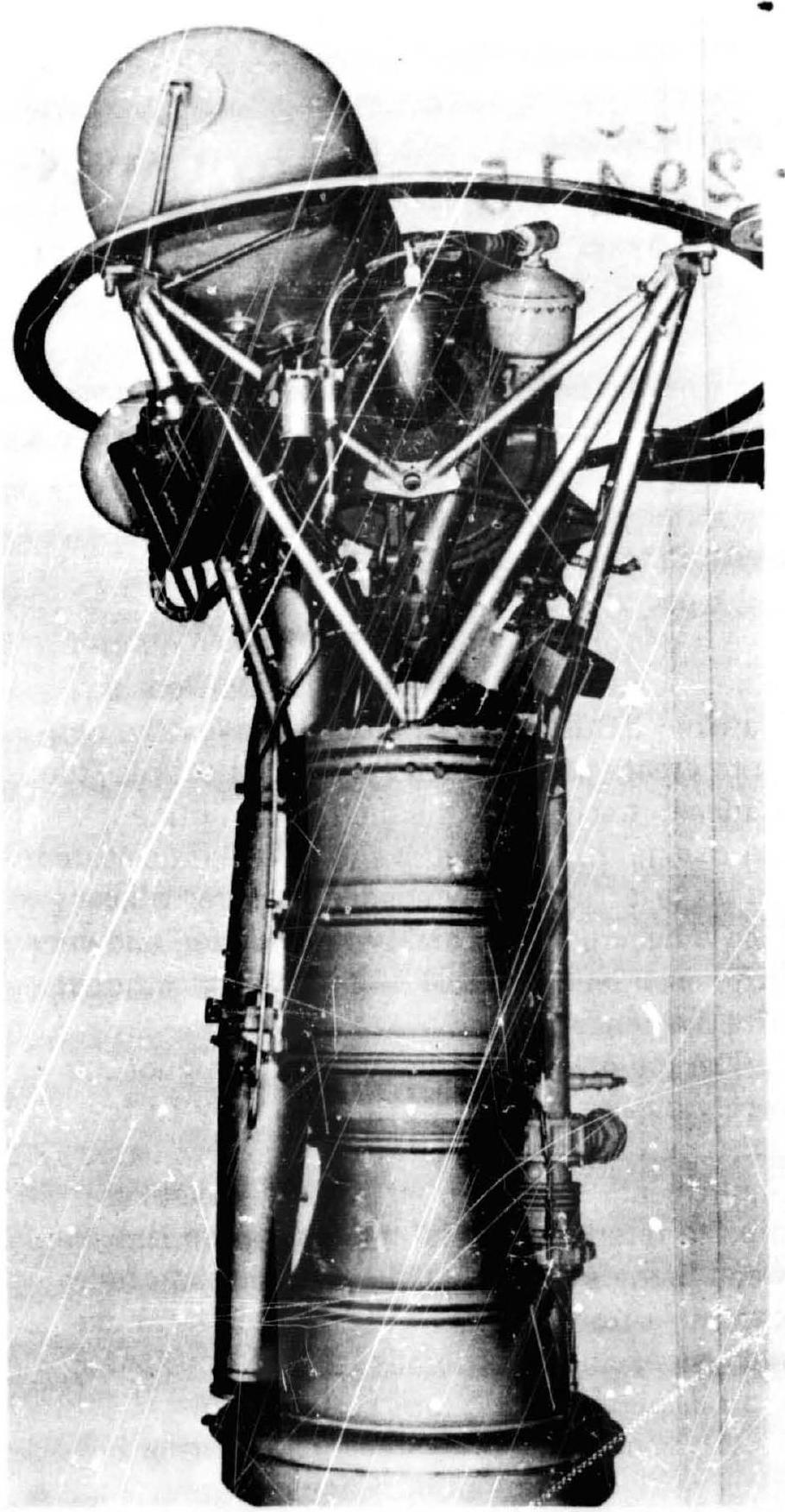

The importance of systems engineering is being recognized to an increasing degree. Figure 10-1 shows the final configuration of the engine for an early postwar ballistic missile. Comparing this to figure 2-4 we realize the progress made through good systems engineering. However, to have designed and developed a goodlooking, perfectly functioning rocket engine is not enough.

It may appear superfluous to state that the design of rocket engines must also consider vehicle application. Yet in the daily grind of problem solving, engine detail design and development, this is easily forgotten. The rocket engine and component designer and developer who can think and converse in terms of vehicle application will be sought after indeed, and so will be the company he represents.

Figure 10-1.-Ballistic missile liquid rocket engine showing greatly inproved simplicity.

Figure 10-1.-Ballistic missile liquid rocket engine showing greatly inproved simplicity.

Rocket engine design for vehicle application is a consideration not only for vehicle flight or for optimum mission performance. Long before the engine will fly, and after it has been designed and developed, it must be installed. The facets of engine installation in a vehicle range from more complex areas, such as guidance loop compliance and prestart conditioning to simple "nuts and bolts" problems, such as matching connecting fitting dimensions and attachment bolt sizes.

We can easily realize the importance of continuous and close communication between engine designer and vehicle builder. Complete and free exchange of correspondence, documentation and progress reports, frequent design reviews, and above all, prompt notification of changes is vital. During engine development, closest simulation of flight vehicle configuration, when performing static engine development tests, will materially reduce the possibility of later "surprises." Each vehicle type, according to its mission, will have somewhat different interface problems. Many of these occur, however, in almost any vehicle type.